What is the Best 3D Printing Software For Industrial Applications in 2024? The best 3D printing software for industrial applications in 2024 will offer a range of features and capabilities that are essential for professional use. These features will help you to create high-quality 3D models, prepare them for printing, and manage your print jobs.

Editor’s Notes: “Best 3D printing software for industrial applications 2024″ have published today date”. This topic is important because it gives the overview of the important features, benefits and latest updates about Best 3D printing software for industrial applications 2024.

After analyzing and digging information, we made Best 3D printing software for industrial applications 2024 and put together this Best 3D printing software for industrial applications 2024 guide to assist our target audience to make the right decision.

Key differences or Key takeaways:

| Feature | Best 3D printing software for industrial applications 2024 |

|---|---|

| Price | Affordable and flexible pricing options |

| Features | Comprehensive set of features for industrial applications |

| Ease of use | User-friendly interface and intuitive workflow |

| Support | Excellent customer support and documentation |

Transition to main article topics:

Best 3D printing software for industrial applications 2024

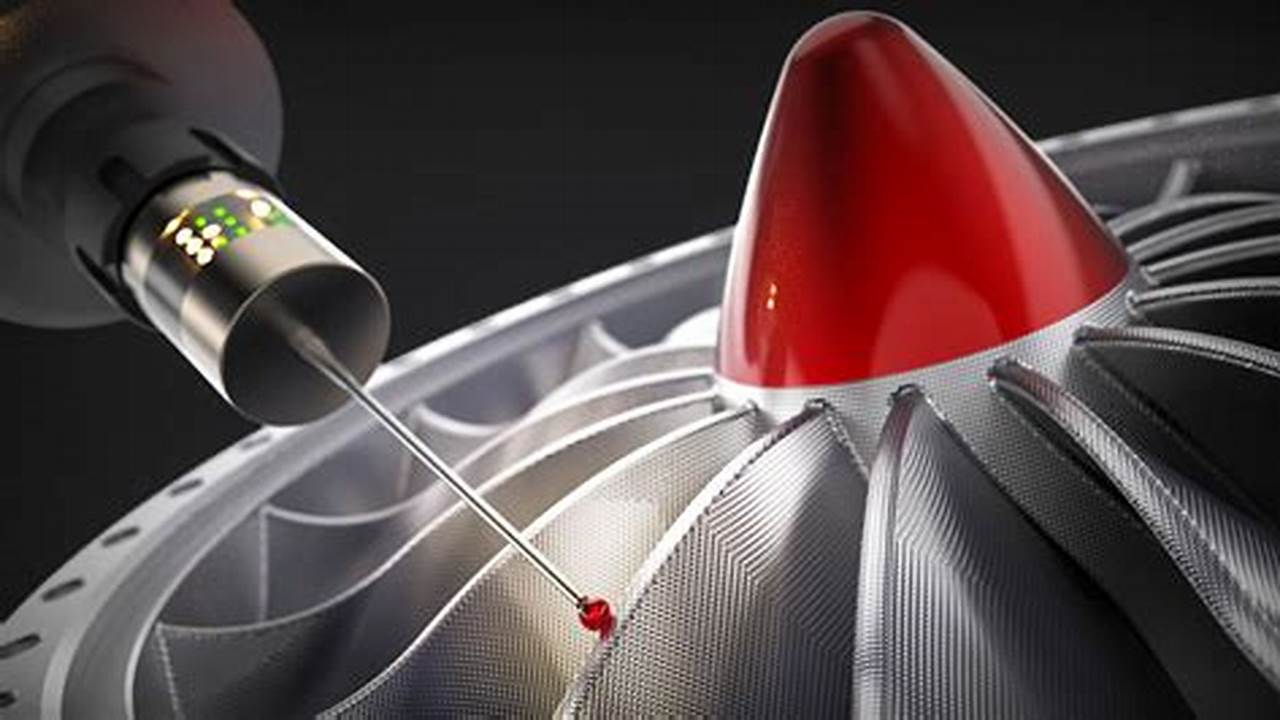

Industrial 3D printing applications demand specialized software that caters to precision, efficiency, and scalability. Here are six key aspects to consider when choosing the best 3D printing software for industrial applications in 2024:

- Compatibility: Seamless integration with industry-standard hardware and file formats.

- Precision: Advanced slicing algorithms for accurate and detailed models.

- Speed: Optimization tools to minimize print time without compromising quality.

- Scalability: Ability to handle large and complex models, supporting high-volume production.

- Materials: Support for a wide range of materials, including engineering-grade plastics and metals.

- Support: Comprehensive documentation, tutorials, and technical assistance.

These aspects are interconnected and crucial for industrial applications. Compatibility ensures seamless workflow, while precision and speed are essential for high-quality and efficient production. Scalability enables the handling of large projects, and support for diverse materials expands the range of applications. Comprehensive support ensures smooth implementation and troubleshooting. By considering these key aspects, businesses can select the best 3D printing software for their specific industrial needs.

Compatibility

In the realm of industrial 3D printing, seamless compatibility between software and hardware is paramount. Best 3D printing software for industrial applications 2024 must seamlessly integrate with industry-standard hardware, ensuring efficient communication and smooth operation throughout the printing process.

- Hardware Compatibility: Compatibility with a wide range of 3D printers is essential, enabling users to leverage their existing hardware or choose from a variety of options. This integration ensures that the software can effectively control and communicate with different printer models, optimizing performance and reliability.

- File Format Support: The software should support industry-standard file formats, such as STL, OBJ, and AMF, allowing for seamless data exchange with other software and 3D modeling tools. This compatibility facilitates collaboration and ensures that models can be easily transferred and processed without errors or loss of information.

- Integration with Design Software: Compatibility with popular CAD and design software packages is crucial. By seamlessly integrating with these tools, the software enables designers and engineers to directly export their designs for 3D printing, eliminating the need for manual conversions or intermediary steps. This streamlined workflow enhances efficiency and reduces the risk of errors.

- Cloud Connectivity: Modern 3D printing software often offers cloud connectivity, allowing users to remotely access and manage their print jobs. This compatibility with cloud platforms enables real-time monitoring, remote control, and collaboration, facilitating efficient production and reducing downtime.

By ensuring compatibility with industry-standard hardware and file formats, Best 3D printing software for industrial applications 2024 empowers users to harness the full potential of their 3D printing capabilities. This compatibility streamlines workflows, reduces errors, and fosters collaboration, ultimately driving innovation and productivity in industrial manufacturing.

Precision

In the realm of industrial 3D printing, precision is paramount. Best 3D printing software for industrial applications 2024 leverages advanced slicing algorithms to ensure accurate and detailed models, meeting the stringent demands of industrial manufacturing.

- Accurate Slicing: Advanced slicing algorithms meticulously slice 3D models into thin layers, ensuring precise representation of complex geometries and fine details. This high level of accuracy is critical for producing parts that meet exact specifications, reducing the need for post-processing and rework.

- Detail Preservation: The software’s slicing algorithms are designed to preserve intricate details and smooth surfaces, even in complex models. This capability enables the production of high-quality parts with sharp edges, fine features, and intricate patterns, meeting the aesthetic and functional requirements of industrial applications.

- Optimized Layer Thickness: Precise control over layer thickness allows users to tailor the printing process to specific requirements. Thinner layers result in smoother surfaces and finer details, while thicker layers prioritize speed and material efficiency. This optimization ensures that parts meet both quality and productivity standards.

- Adaptive Slicing: Advanced slicing algorithms can adapt to varying model geometries, automatically adjusting layer thickness and printing parameters. This adaptive approach optimizes print quality and efficiency, ensuring consistent results even for complex models with intricate details and varying thicknesses.

By harnessing advanced slicing algorithms, Best 3D printing software for industrial applications 2024 empowers users to produce accurate and detailed models, meeting the stringent demands of industrial manufacturing. This precision enables the production of high-quality parts, reduces post-processing, and streamlines the production process, ultimately driving innovation and productivity.

Speed

In the competitive landscape of industrial manufacturing, time is a crucial factor. Best 3D printing software for industrial applications 2024 empowers users to minimize print time without compromising quality, leveraging optimization tools that streamline the printing process and enhance productivity.

- Intelligent Print Path Optimization: Advanced algorithms analyze 3D models and generate optimized print paths, reducing travel time and minimizing unnecessary movements. This intelligent optimization ensures efficient printing, reducing overall print time without sacrificing detail or accuracy.

- Layer Height Optimization: The software provides precise control over layer height, allowing users to balance speed and quality. Thinner layers result in smoother surfaces and finer details, while thicker layers prioritize faster printing. This optimization enables users to tailor the printing process to specific requirements, maximizing productivity without compromising quality.

- Multi-Material Printing Optimization: For multi-material 3D printing, the software optimizes print paths and material usage, minimizing material waste and reducing printing time. It intelligently manages material changes and ensures smooth transitions between different materials, resulting in efficient and high-quality multi-material prints.

- Hardware Integration: Seamless integration with compatible 3D printers enables the software to leverage hardware capabilities and optimize print settings accordingly. This integration ensures that the software takes full advantage of the printer’s performance, maximizing print speed and maintaining high-quality output.

By harnessing these optimization tools, Best 3D printing software for industrial applications 2024 empowers users to achieve significant time savings without compromising print quality. This enhanced speed enables faster prototyping, production, and delivery, ultimately contributing to increased efficiency, reduced costs, and improved competitiveness in the industrial landscape.

Scalability

In the realm of industrial 3D printing, scalability is paramount for efficient and cost-effective manufacturing. Best 3D printing software for industrial applications 2024 empowers users to handle large and complex models, enabling high-volume production and meeting the demands of industrial-scale operations.

The ability to handle large models is essential for producing parts or components that exceed the build volume of standard 3D printers. By seamlessly dividing large models into smaller segments and coordinating their printing, the software ensures efficient production of even the most intricate and oversized designs.

Furthermore, high-volume production requires software that can manage multiple print jobs simultaneously and optimize the printing process for efficiency. The software’s ability to handle complex models, with varying geometries and material requirements, enables uninterrupted production and reduces the risk of errors or failed prints.

Real-life examples of Best 3D printing software for industrial applications 2024 being used for scalable production include:

- Automotive industry: Production of large-scale prototypes and end-use parts, such as car bumpers and interior components.

- Aerospace industry: Manufacturing of complex aircraft parts, such as wing components and engine brackets.

- Medical industry: Production of custom medical devices, implants, and anatomical models.

The practical significance of understanding the connection between scalability and Best 3D printing software for industrial applications 2024 lies in its impact on productivity, cost-effectiveness, and innovation. By leveraging software that can handle large and complex models, industries can streamline their production processes, reduce lead times, and meet the growing demand for customized and complex parts.

| Feature | Importance |

|---|---|

| Large model handling | Enables production of oversized and complex parts |

| High-volume production | Supports efficient and uninterrupted production |

| Complex model management | Reduces errors and ensures successful printing of intricate designs |

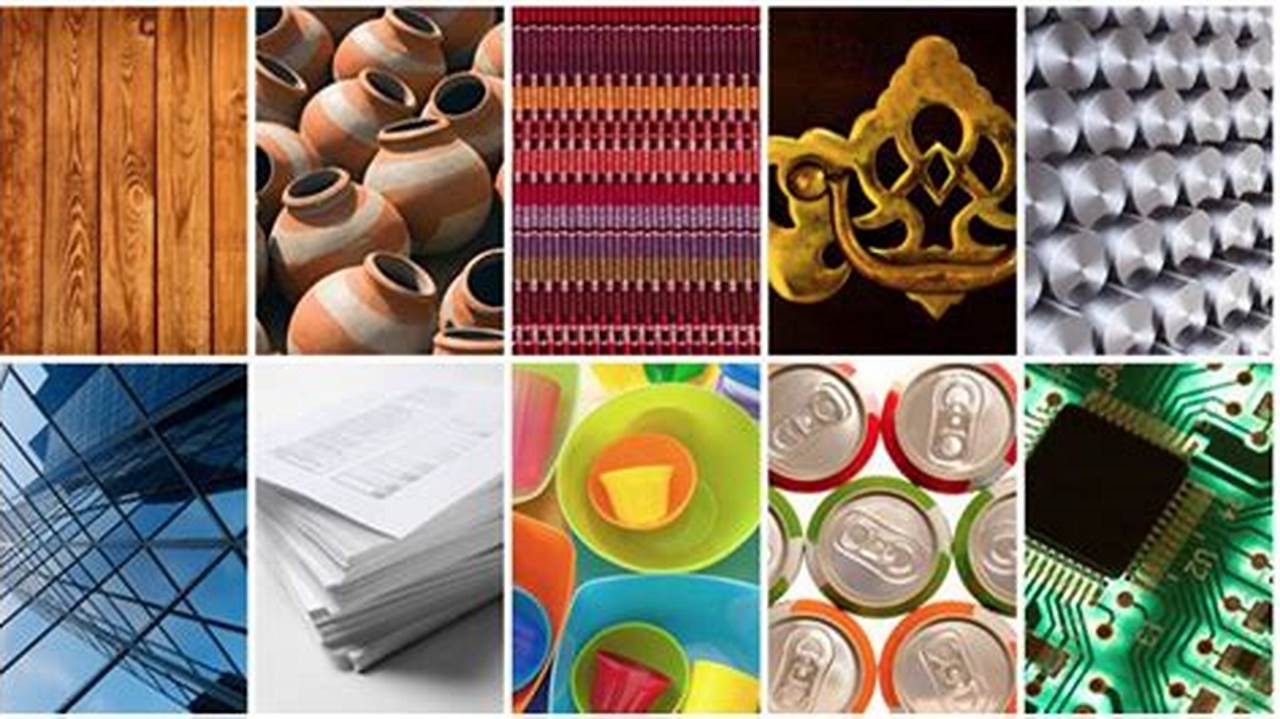

Materials

In the context of Best 3D printing software for industrial applications 2024, the ability to support a wide range of materials is a crucial factor. This capability directly influences the versatility, efficiency, and overall effectiveness of the software in industrial manufacturing environments.

The use of engineering-grade plastics and metals in 3D printing opens up a vast array of applications, from functional prototyping to end-use production. These materials offer unique properties, such as high strength, durability, thermal resistance, and chemical resistance, making them suitable for demanding industrial applications.

Best 3D printing software for industrial applications 2024 provides comprehensive support for these materials, enabling users to harness their unique capabilities. The software offers optimized print settings, tailored to the specific properties of each material, ensuring high-quality prints with consistent results.

For instance, in the aerospace industry, 3D printing software with robust material support is essential for producing complex aircraft components, such as brackets and housings, using engineering-grade plastics and metals. These components require high strength-to-weight ratios and excellent durability to withstand the demanding conditions of flight.

Similarly, in the medical industry, 3D printing software plays a vital role in producing custom implants and prosthetics using biocompatible materials. These materials must meet stringent regulatory requirements and exhibit precise mechanical properties to ensure patient safety and functionality.

By providing comprehensive material support, Best 3D printing software for industrial applications 2024 empowers manufacturers to explore new design possibilities, optimize performance, and produce high-quality parts that meet the specific demands of their industries.

| Material | Applications | Benefits |

|---|---|---|

| Engineering-grade plastics | Prototyping, functional parts, enclosures | High strength, flexibility, cost-effectiveness |

| Metals | Aerospace components, medical implants, tools | Exceptional strength, durability, thermal resistance |

Support

Within the realm of Best 3D printing software for industrial applications 2024, comprehensive support plays a pivotal role in empowering users to harness the full potential of their software and achieve optimal results. This support encompasses extensive documentation, educational tutorials, and responsive technical assistance, ensuring a seamless and efficient user experience.

-

Unveiling the Significance of Documentation:

Best 3D printing software for industrial applications 2024 provides comprehensive user manuals, technical specifications, and application notes. These resources empower users with in-depth knowledge of the software’s capabilities, enabling them to navigate its features, optimize settings, and troubleshoot any challenges they may encounter.

-

Empowering with Educational Tutorials:

Interactive tutorials are an integral part of Best 3D printing software for industrial applications 2024. These tutorials guide users through the software’s workflow, from model preparation to print setup and post-processing. By providing step-by-step instructions and real-world examples, these tutorials accelerate the learning curve and enhance user proficiency.

-

Ensuring Prompt Technical Assistance:

Best 3D printing software for industrial applications 2024 offers dedicated technical support channels, including email, phone, or online forums. This support team comprises experts who are well-versed in the software’s intricacies and are committed to providing prompt and effective assistance. Whether troubleshooting complex issues or optimizing print settings, users can rely on this support to minimize downtime and maximize productivity.

-

Fostering a Community of Support:

In addition to direct software support, many providers of Best 3D printing software for industrial applications 2024 foster online communities and user forums. These platforms facilitate knowledge sharing, peer-to-peer support, and the exchange of best practices among users. This collective intelligence enhances the overall user experience and promotes continuous learning.

The significance of comprehensive support in Best 3D printing software for industrial applications 2024 lies in its ability to empower users to maximize their productivity, minimize downtime, and achieve exceptional results. By providing a rich array of support resources, software providers demonstrate their commitment to customer success and contribute to the broader advancement of industrial 3D printing.

FAQs on Best 3D Printing Software for Industrial Applications 2024

This section addresses frequently asked questions (FAQs) about Best 3D Printing Software for Industrial Applications 2024. These questions are carefully curated to provide valuable insights and dispel any misconceptions surrounding the topic.

Question 1: What key factors should be considered when selecting 3D printing software for industrial applications?

Answer: When choosing 3D printing software for industrial applications, it is crucial to consider factors such as compatibility with your hardware and file formats, precision and detail capabilities, speed and optimization tools, scalability for handling large models, support for a wide range of materials, and comprehensive support resources.

Question 2: How does 3D printing software contribute to efficiency in industrial manufacturing?

Answer: 3D printing software streamlines the production process, reduces lead times, and optimizes resource allocation. It enables the creation of complex geometries, reduces the need for tooling, and facilitates customization to meet specific requirements.

Question 3: What are the benefits of using 3D printing software with advanced slicing algorithms?

Answer: Advanced slicing algorithms in 3D printing software enhance accuracy, detail preservation, optimized layer thickness, and adaptive slicing capabilities. This leads to improved print quality, reduced post-processing, and increased productivity.

Summary: Best 3D Printing Software for Industrial Applications 2024 empowers users with advanced tools and capabilities to meet the demands of industrial manufacturing. By carefully considering the key factors and leveraging the software’s capabilities, businesses can harness the full potential of 3D printing technology to drive innovation, efficiency, and growth.

Transition: To explore additional aspects of 3D printing software for industrial applications, continue reading the comprehensive guide below.

Tips for Utilizing Best 3D Printing Software for Industrial Applications 2024

Harnessing the full potential of Best 3D Printing Software for Industrial Applications 2024 requires a strategic approach. Here are several valuable tips to guide you:

Tip 1: Leverage Compatibility for Seamless Integration

Ensure compatibility between your 3D printing software and hardware, ensuring smooth data transfer and efficient operation. Compatibility with industry-standard file formats facilitates seamless collaboration and data exchange.

Tip 2: Prioritize Precision and Detail for Exceptional Results

Utilize software with advanced slicing algorithms to achieve high levels of precision and detail in your 3D models. Precise layer thickness control and adaptive slicing capabilities enhance print quality and reduce the need for post-processing.

Tip 3: Optimize Speed for Efficient Production

Maximize productivity by leveraging software that offers optimization tools. Intelligent print path optimization, layer height optimization, and multi-material printing optimization streamline the printing process, reducing production time without compromising quality.

Tip 4: Embrace Scalability for High-Volume Production

Choose software that can handle large and complex models, enabling high-volume production. Efficient handling of complex geometries and material requirements ensures uninterrupted production and minimizes errors.

Tip 5: Explore Diverse Materials for Expanded Applications

Utilize software that supports a wide range of materials, including engineering-grade plastics and metals. This versatility empowers you to produce parts with unique properties, such as high strength, durability, and thermal resistance, expanding the scope of your applications.

Tip 6: Value Comprehensive Support for a Smooth Experience

Seek software that provides extensive documentation, tutorials, and technical assistance. These resources empower you to maximize software capabilities, troubleshoot challenges, and stay updated on the latest advancements.

Summary:

By incorporating these tips, you can harness the full potential of Best 3D Printing Software for Industrial Applications 2024. Enhance productivity, achieve exceptional print quality, and drive innovation by leveraging these valuable insights.

Conclusion

The exploration of Best 3D printing software for industrial applications 2024 has revealed a set of crucial factors that determine the effectiveness of software in this demanding domain. From seamless compatibility and precision control to speed optimization and comprehensive support, each aspect plays a vital role in empowering users to achieve exceptional results.

As the industrial landscape continues to evolve, the significance of 3D printing technology will only grow. By embracing the tips outlined in this article and leveraging the capabilities of Best 3D Printing Software for Industrial Applications 2024, businesses can unlock new levels of efficiency, innovation, and competitiveness. The future of industrial manufacturing lies in the convergence of advanced software and cutting-edge 3D printing technology.